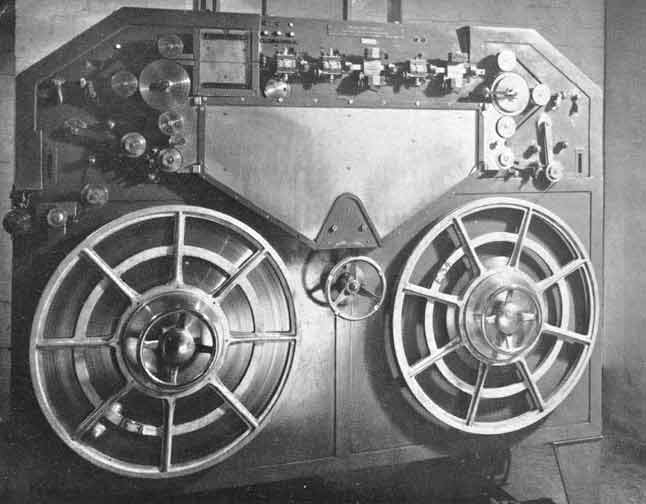

The first of these new Marconi-Stille machines was delivered to Maida Vale in March 1935, two more were operational in May and the fourth arrived in July. A further two machines, ordered in June, were delivered in September.

The Marconi-Stille machines proved to be more reliable than the Blattners, with most problems caused by tapes breaking at the joints and some amplifier and electrical faults. The frequency response was +/-2dB from 100Hz-6kHz and a signal to noise ratio of 35dB or better could be achieved. The final machine was withdrawn from service around 1950.

The tungsten steel tapes were of Swedish manufacture, 3mm wide and 0.08mm thick. Three 1000m lengths were silver-soldered together to give a spool which played for about 32 minutes and weighed 25lbs. A tape and spool cost about £21. The tapes were re-used so the average cost worked out at about 6d (2.5p) a minute. They could be edited, each joint being soldered or welded, though when there were about a dozen edits in a tape it was scrapped because of the increased risk of damage to the head pole pieces caused by the lapped joints.

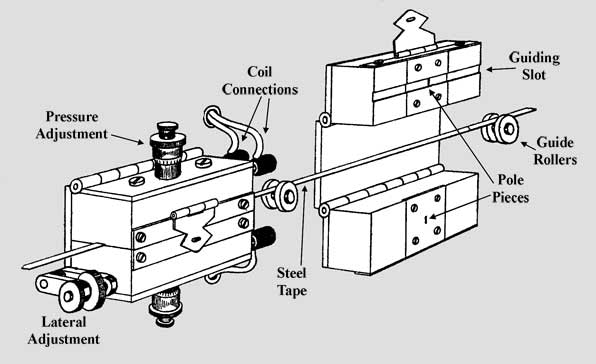

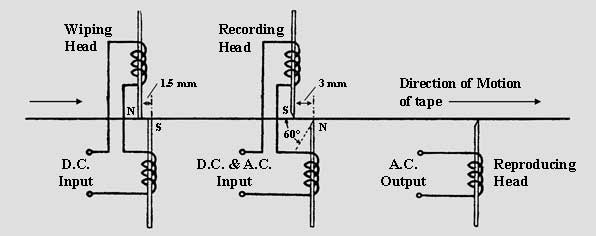

The diagram above shows a couple of the heads. These consisted of two small hinged 'boxes' which closed together around the tape. A slot guided the tape past the two pole pieces which touched the tape at right angles. A screw and spring arrangement controlled the pressure of the heads on the tape. The pole pieces were not directly opposite one another but slightly staggered - about 1.5mm for the erase (or wiping) head and 3mm for the record one. A lateral adjustment screw controlled the offset. The erase pole pieces were made of Stalloy and had a flat contact surface with the tape. The record ones were also of Stalloy but had a knife edge to improve high frequency performance. The replay pole piece was made of Permalloy and also had a knife edge.

A small coil of wire was wound around each of the pole pieces. The first head had a direct current of about 20mA passed through its coils which magnetised the tape to saturation, thus erasing any previous recording. The record head was fed with a direct current opposite in polarity to that on the erase head onto which was superimposed the alternating current of the signal to be recorded. The play head had a pole piece on only one side of the tape. The presence of separate record and play heads allowed 'off-tape' monitoring while recording.

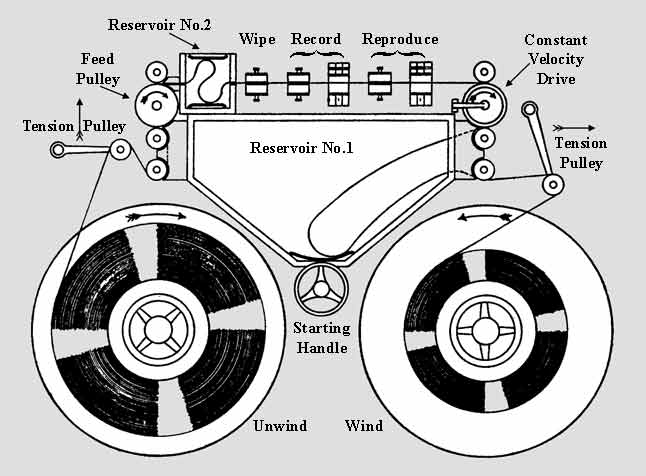

The machine used three motors. An A.C. synchronous motor was used to draw the tape past the heads. A second motor drove the feed pulley which pulled tape off the left hand spool. This ran slightly fast allowing a loop of tape to build up in the reservoir no.2 to the left of the heads. When the loop was large enough it touched contact strips inside the reservoir and thus removed the bias from the grid of a thyratron. A relay in the anode circuit operated and switched a resistance into the motor circuit, thus slowing the feed pulley. As soon as the loop reduced in size the motor returned to normal speed. Using a thyratron required only small currents to pass through the tape - the larger currents that using a relay directly would have required might have put clicks onto the recording. The third motor, driving the right hand spool, was controlled in a similar way. It ran slightly slow allowing the tape to build up in reservoir no.1. The contact strip at the bottom of the reservoir operated another thyratron. These arrangements prevented any extra load being put onto the constant speed motor and thus slowing it down.

The tape could be rewound at about double speed, a loop forming on the left of reservoir no.1 being used to control the relative speed of the motors. The constant-speed drive system was disconnected by an automatic release clutch during the rewind.

The replay amplifier was a standard BBC type A, modified to provide the required equalisation. A power output stage fed the monitoring loudspeaker. The head driving amplifier was specially designed.

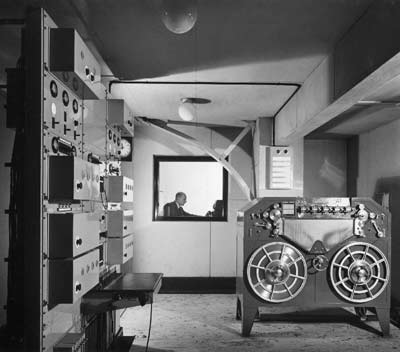

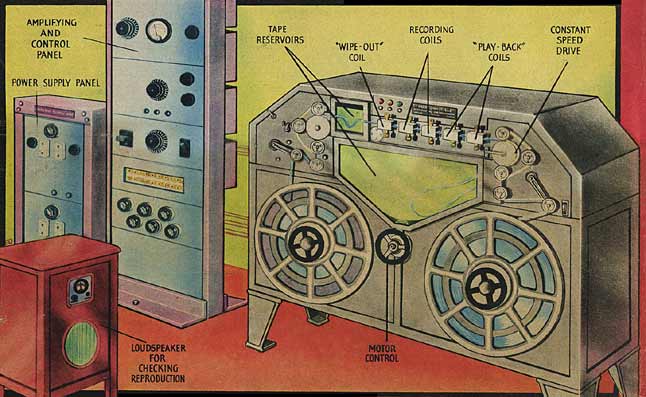

Here's a contemporary view of the machine, from 'Modern Wonder', September 1937:

The magazine wrote: 'One of the wonderful machines in use by the BBC is the Marconi-Stille magnetic recorder-reproducer. This instrument enables broadcast speeches and music to be "stored" on a long steel ribbon by magnetism so that they may be re-broadcast at any time.....The machine comprises two large drums on which special steel tape is wound by means of an electric motor. Between the drums, electro-magnets are arranged, and the tape passes between the pole-pieces of these magnets. The impulses in the coils of the electro-magnets cause the tape to be magnetized in larger and smaller amounts, and when the tape has been treated, it forms a highly accurate record of speech and music.'